Gallery

Behind the Scenes: How We Prepare Every Bale for Export

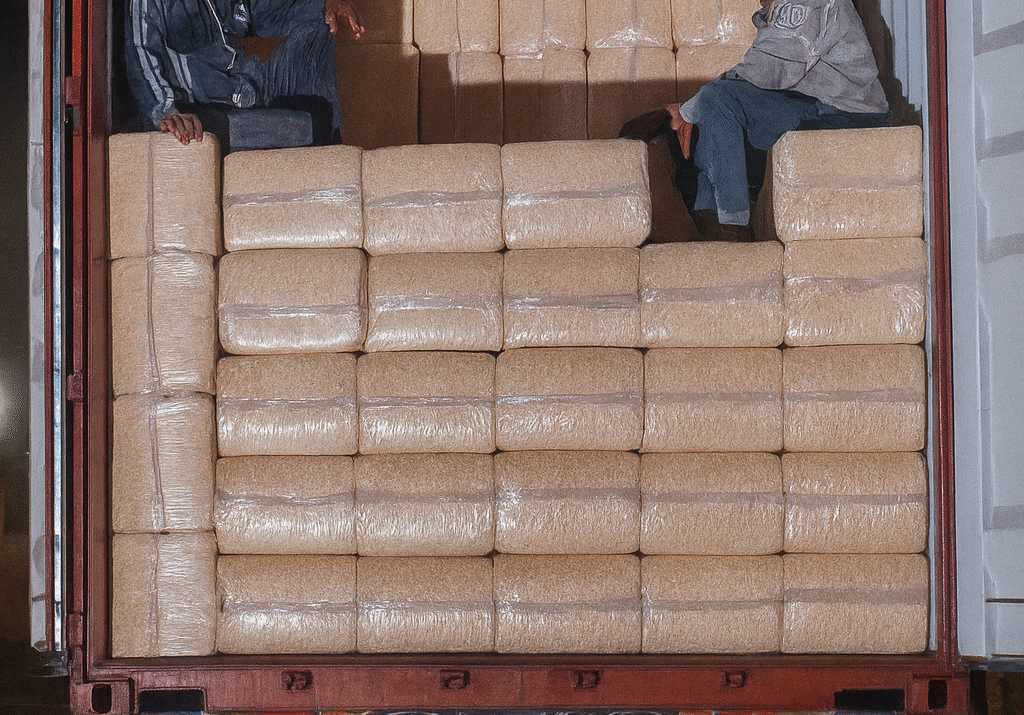

A real-world view of stacking, aligning, and securing our premium sawdust bales inside the container—showing the reliability, stability, and craftsmanship behind each shipment.

Clean, Compressed Sawdust Bales Prepared for Heavy-Duty Loading

Our sawdust bales are tightly compressed, dust-controlled, and shaped with consistent density—making bulk loading easier, cleaner, and more efficient. This video showcases how we prepare every bale with precision to ensure stable stacking and reliable performance during transport.

Precision Alignment for Maximum Loading Stability

Our team manually positions each sawdust bale to eliminate gaps, improve balance, and enhance load stability. This meticulous alignment ensures every container is packed safely, cleanly, and efficiently—maintaining the integrity of each bale throughout transport.

Maximum Load Efficiency for Bulk Export

Our sawdust bales are engineered for optimized stacking, allowing exporters to load more volume per container without compromising product integrity. This efficient packing method reduces shipping costs, maximizes container space, and ensures every shipment arrives clean, stable, and ready for use.

Clean, Dust-Controlled Storage You Can Trust

Stored in a controlled, dust-reduced environment, our sawdust bales remain clean, compact, and easy to handle. Every stack is organized for maximum hygiene, long-term stability, and safe, contamination-free storage.

Uniform Bale Structure for Reliable Handling

Our sawdust bales are crafted with consistent shape, clean edges, and stable compression—making stacking, storage, and daily handling easier, faster, and far more efficient. Each bale maintains the same dimensions and density, ensuring predictable performance and a perfectly organized workflow.

High-Density Sawdust Blocks Engineered for Stable Stacking

Our precisely compressed sawdust bales are designed to maintain shape and stability during storage. Each block is compacted to ensure uniform density, preventing deformation, reducing space waste, and guaranteeing a clean, efficient workflow inside the production facility.

High-Volume Loading with Consistent Quality Assurance

This spacious loading setup is designed to handle large quantities of premium sawdust while maintaining strict quality standards in every bale. Even at high volumes, each unit retains its density, cleanliness, and structural integrity—ensuring reliable performance throughout the entire shipment.

Human-Assisted Packing for Guaranteed Bale Integrity

Each bale is manually positioned and double-checked by our on-ground team, ensuring secure placement, clean alignment, and damage-free loading—even during high-volume night operations. This hands-on approach guarantees that every shipment leaves the facility with maximum care and zero compromise.